How machines run for a long time without problems is important for keeping work fast and costs low. If equipment is not lubricated well, the performance drops and fresh parts are needed early, which makes costs go higher. Before, people used old lubrication methods by hand, but that way often made mistakes, stopped work, and broke equipment soon. Now, many industries in Australia use automatic lubrication systems, which are better and improve results. Auto lube systems put the exact amount of lubricant on parts at set times, not needing people to do the job. These systems run when the machine works, so all parts that need oil always get it. When lubrication is steady and correct, machines escape from too much or too little lubrication, which may hurt them. Mining, farming, making products, and moving goods in Australia all use these systems more often now.

How Automatic Lubrication Systems Work?

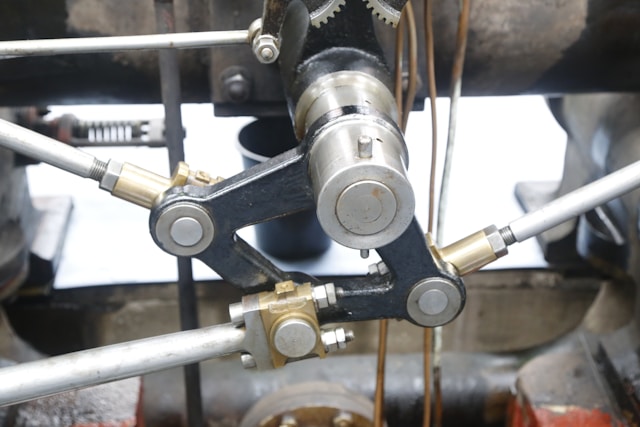

Most automatic lubrication systems have a main pump or tank, small devices that divide the oil or grease, and pipes that take the lubricant to every needed place. When you start the system, it moves a planned amount of lubricant and shares it out evenly. It can work with both oil and grease, depending on what the machine and the working area need. Most of the time, a controller or timer tells the system when to add more lubricant, based on how long and how hard the machine works. Sometimes, sensors watch the pressure and flow, making sure work is smooth and letting the operator know if there is a problem. This kind of system is very good for machines with hard-to-reach spots, and it saves time by removing the need to do it by hand in tricky or risky spots.

Reducing Wear and Tear on Equipment

By using automatic lubrication systems, the machine parts wear down much less. Friction is one of the things that damages parts the most, and short times without proper oiling can make expensive problems. When a lubrication system keeps a thin oil layer all the time, it protects the machine’s moving areas like bearings, gears, and chains from touching each other. Australia has mining places with dust and farms with moisture, so steady lubrication is a must. With auto systems, dirt cannot go in when people do greasing, and all the moving parts keep working with less risk. Machines run better, with less heat, and parts do not get tired out fast.

Extending Machinery Lifespan

Another big gain from auto lubrication is the machine stays in use for longer years. With correct and steady oil, the moving pieces do not get strained, so they are less likely to break and last longer. This point means a lot to users who buy costly, big machines that may work for mining or farming, since a breakdown cuts profits and makes everyone wait. In Australia, work is sometimes far from towns, so keeping machines working longer means less fixing on site. With less damage during use and machines always in good order, companies keep their expensive trucks and harvesters safe for more time.

Improving Operational Uptime

Bad timing of repairs can stop factories or transport work, so making sure machines keep working is key. The best way to skip these breaks is to have equipment that stays in good shape always. Automatic lubrication systems help this happen by managing a daily, needed task without people checking each time or doing repairs at the last second. In the plants and truck yards that run all day, any stop can cause big slowdowns. By using automatic lubrication, oiling and greasing happen as the machine does its job, which keeps the work flowing and lets no time go to waste. Australia’s places with many mines or big crops rely heavily on these systems for meeting their daily and monthly plans.

Supporting Safe and Sustainable Maintenance Practices

Safe work and less pollution are more important now than ever in Australia’s industries. Automatic lubrication drops the number of times people must get close to moving machines, which lowers injury risk and helps keep up with safety laws. Taking care of the environment also means not wasting oil and keeping it off the ground or water. These systems are careful to use just the right amount of grease or oil and stop extra leaks or spills that hurt nature. If work is close to clean rivers or protected land, meeting legal rules is easier with automatic oiling systems. Right now, using automatic lubrication systems in machines makes sense in many ways. Companies find these systems make looking after machines simple, they save money, and they keep people and nature safe while doing the job well. Australian industries are seeing automatic lubrication as a smart move, and with more use, the positive changes become easier to notice.