Choosing the right lathe machine for your workshop can feel like navigating a maze. With so many choices available, it’s easy to feel confused. No matter if you’re an experienced maker or a beginner, choosing the right lathe is important for getting precise and high-quality results in your work. This tool is not just for rearranging content; it helps you boost imagination and improve your skills.

Picture turning regular wood into beautiful art effortlessly. A lathe machine can help you reach your goals, but you first need to know what works best for you. When choosing a lathe, you need to consider different types and important aspects that improve its use. Let’s dive deeper into how to find the ideal lathe for your workspace without breaking a sweat—or the bank!

Different types of turning machines and what they do

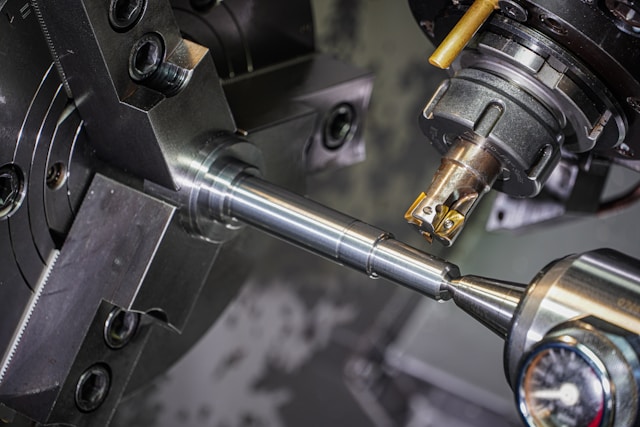

There are different types of lathe machines for sale, and each one is made for certain jobs. The most popular type is the wood lathe, which is great for making furniture and decorations. It lets you easily shape and cut wood. Next is the metal lathe. This strong machine is used for cutting and bending metal, which makes it very important for workers in machining and engineering. It’s great for detailed work on parts like shafts or gears. For people who work with bigger products, there’s a bench lathe. This option is small but strong, making it great for small jobs without taking up too much space.

CNC lathes have become more popular lately. These machines run on computers and provide accuracy and automation. They are ideal for producing big quantities where uniformity is important. Knowing these types can help you pick a machine that fits your workshop’s goals and needs.

Things to think about before getting a lathe machine

There are several things to consider when getting a lathe machine. First, consider how big your workshop is. Make sure you have enough room for the machine and your projects. Think about the kinds of things you will use. Some tools are great for woodturning, while others work better for metalworking. Using the right lathe for your main object will make your work better and faster.

Power needs are important, too. A stronger motor enables quicker cutting speeds and can work with harder materials. Figure out how strong your machine needs to be based on what you plan to do with it. Remember to consider how easy it is to use and take care of. A simple design makes it quicker to set up and use, and regular maintenance helps it work well for a long time. Look into warranty choices or customer support from the manufacturers. These can be really helpful if problems come up later.

Affordable choices vs. expensive machines

When choosing a turning machine, your budget is usually very important. Affordable choices are great for hobbyists or small workshops. They typically have basic features and enough strength to manage simple jobs effectively. High-end tools provide better features and more accuracy. These types are usually made with better quality materials and parts that make them last longer.

Buying a high-quality lathe can greatly improve efficiency for professionals working on detailed tasks. It’s important to evaluate your wants before making this decision. If you’re new or doing easier jobs, mid-range options could be a good choice because they offer better value without too many extra features. Checking your project needs will help you find the best group that matches your workshop goals while staying within budget.

Essential features for a flexible cutting machine

When choosing a lathe machine, certain aspects can greatly improve its flexibility and ease of use. First, think about the motor power. A strong motor lets you work with different materials easily. Choose machines that have variable speed settings because this allows you to adjust them for different jobs. Another important aspect is the length of the bed. A longer bed gives you more stability for bigger projects while still making it easy to work on smaller ones. Make sure your lathe is well-built. This will stop noises while it runs and help improve accuracy.

How well the tool rest can adjust can affect how smoothly you work. Quickly changing the height or position of the tool rest gives you better control of your cuts. Don’t forget about digital readouts; they give accurate measurements and help you make your workpieces exact. Look at accessories like chucks and faceplates that either come with the machine or can be bought separately. They help you do more and make a wider range of projects. With these important features in mind, you’ll be ready to select a lathe machine that fits your current wants and future plans for your workshop.